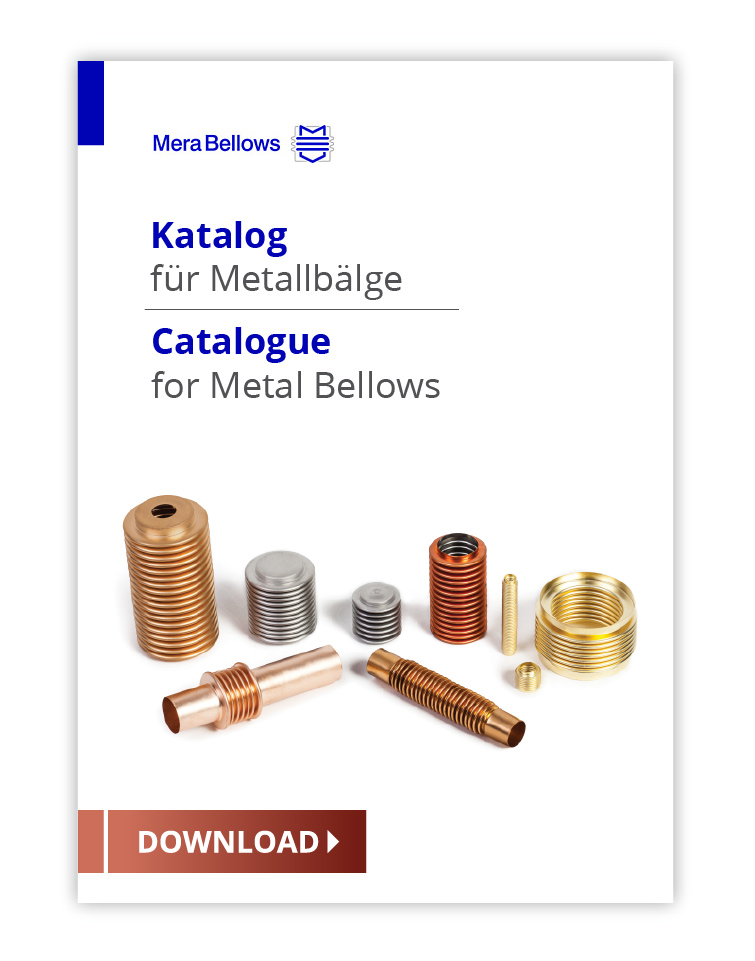

Our products

Hydro formed bellows, Deep drawn tubes & Stainless steel expansion joints

Our products

Hydro formed bellows

Our metal bellows are available in a remarkable precision and may be supplied in a wide range of welded or seamless designs and bottom shapes. Specialized as manufacturer for hydroformed metal bellows we supply those made of different nonferrous metals, stainless steels and other alloys – e.g. for pressure switches or valve stem assemblies

The product range of Mera Bellows

At Mera Bellows, we are specialized in the production of custom engineered high-precision metal parts: Our deep-drawn seamless tubing is used as a basis to manufacture hydro formed bellows and thin-walled expansion joints for numerous industries that demand long-lasting, maintenance-free and non-leaking components.

Since 2000, Mera Bellows Sp. z o.o. is part of a German Holding company and certified according to ISO-9001 & ISO-14001. The firm’s lean-manufacturing approach guarantees industry competitiveness and continuous improvement. Metallographic examination and different possibilities for stress-analysis, spring rate measurement, and life cycle testing help during prototyping phase and finally ensure that only excellent bellows are supplied in series production.

Deep drawn tubes for seamless precision bellows

The core of a high-quality corrugated bellows is the thin-walled tube of which it is made. Therefore, metal bellows manufacturers must pay rigorous attention to low tolerances of the intermediate products. Using bellows as stainless steel expansion joints (compensators) to absorb movements, welded tubing may be sufficient. To reach highest accuracy, very long cycle-life or for usage in ultra-high vacuum equipment, we often advise seamless designs to best meet the requirements – many bottom shapes are possible that simplify the installation.

At Mera Bellows, only raw material with origin of the European Union is used. Continuous production control is applied. In repetitive cycles of annealing, deep-drawing and washing processes, from the initial metal strip (coil) we achieve the final tube.

Hydro formed metal bellows for cost-effective solutions

The process of hydroforming is ideal for large-scale manufacturing. The convolutions are formed in a time saving one step process – using a bellows-specific cassette that defines the final corrugation structure – having an impact on the performance characteristics, such as stroke or spring-rate. For high-pressure applications, two-ply designs should be considered.

Seamless metal bellows

Hydroformed seamless precision bellows of brass, bronze, stainless steel and special alloys

Open-ended metal bellows – Closed-ended metal bellows – Double-Ply Bellows

Open-ended metal bellows:

Efficient hydroforming technology

Mera Bellows applies hydro-forming to obtain the bellows convolutions. In order to supply open-ended seamless bellows, the closed ends of the tubes are cut using an additional working step. This production process takes great advantage of automated handling and leak testing. The ends of the bellows can be chosen in almost any shape. We have a long standing proven record in processing bronze, brass and different kinds of stainless steels. Mera Bellows is also able to handle special materials like e.g. Monel and Beryllium-Copper alloys.

Applications: Sealing elements (bellows valves, vacuum chambers), flexible connectors, (differential-) pressure transmitters, metal bellows couplings.

Available bellows sizes – Table

| Min [mm] | Max [mm] | |

|---|---|---|

| Inside-Ø | 4,2 ± 0,1 | 70,0 ± 0,3 |

| Outside-Ø | 6,0 ± 0,2 | 100 ± 0,5 |

| Wall thickness | 0,065 ± 0,004 | 0,40 ± 0,025 |

Table: Minimum and maximum bellows diameter

Closed-ended metal bellows

made of seamless precision tubes

Mera Bellows production techniques allow the option of one closed end.

The bottom of our metal bellows can be formed in almost any way. Connection points or other design features may be integrated to meet your specific requirements.

Different bottom shapes

Advantages: The force transmission through the use of our metal bellows is possible without additional soldering or welding. Thus, the customer is able to save valuable working time and resources. Additionally the customer has the ability to resolve any problems that could arise from soldered or welded seams.

Applications: Pressure- or temperature sensing in the measurement and control technology: As actuators in Aerospace or Industrial pressure switches, transducer (in self-regulating thermostats for residential or Automotive use), Aneroid sensors, launch vehicles (satellite technology).

Available bellows sizes – Table

| Min [mm] | Max [mm] | |

|---|---|---|

| Inside-Ø | 4,2 ± 0,1 | 70,0 ± 0,3 |

| Outside-Ø | 6,0 ± 0,2 | 100 ± 0,5 |

| Wall thickness | 0,065 ± 0,004 | 0,40 ± 0,025 |

Table: Minimum and maximum bellows diameter

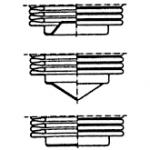

Double-Ply Bellows:

Better safe than sorry

Mera Bellows has a long-standing tradition in producing two-ply metal bellows. In order to produce such special bellows, two tubes have to be fit into each other before forming the convolutions. In doing so, one has to pay a great deal of attention and accuracy to the diameter of the tubes and to scrupulously clean the surface.

Cross section of a two-ply bellows

The most common Application is the use of a flexible sealing element. The great advantage of double-ply bellows is the high reliability against leaking – primarily at high working pressures: In the case of one wall breaking, the other one is still working as a seal.

Available bellows sizes – Table

| Min [mm] | Max [mm] | |

|---|---|---|

| Inside-Ø | 4,2 ± 0,1 | 70,0 ± 0,3 |

| Outside-Ø | 6,0 ± 0,2 | 100 ± 0,5 |

| Wall thickness | 0,065 ± 0,004 | 0,40 ± 0,025 |

Table: Minimum and maximum bellows diameter

Precision tubes

Deep-drawn tubes with ultra-low wall-thicknesses

Seamless tubes made by Mera Bellows:

Precise deep-drawing guarantees low tolerances

Mera Bellows tubes are seamless and their closed end can be formed in almost any way. If open-ended thin-wall tubes are requested, we can cut the bottom. Wall-thicknesses start from 0.064mm. Due to our manufacturing techniques, it is possible to achieve precisions as low as 0.1 mm to 0.4 mm in diameter and of 0.004 to 0.015 mm in wall thickness. We are proud of the exceptional wall to diamater ratios that we can realize. Also special shapes such as axial ribs can be hydroformed which allows R&D activities in various fields and applications. Our deep-drawn tubes are suitable for further plastic deformation on customer side. On demand we supply in annealed condition according your specifications.

Mera Bellows produces thin-wall tubes up to ca. 50mm diameter and a max. length of 450 mm in bronze, brass, stainless steel, monel or beryllium-copper (CuBe2) alloys. Precision tubes in pure Copper, Aluminium or Ni-Cr-Mo alloys are not part of our product portfolio.

The chart shows the tube sizes that Mera Bellows is able to produce.

The tube-length “L” is plotted against the diameter “D” and the wall thickness “d”.

Applications of our customers:

Stainless steel sensor housings (incl. sub-sea usage), medical engineering, plug connections, cartridge/ brass housings, liquid distribution, heater cups for reduced-risk tobacco products (holder tube for the tobacco sticks in vapor-/e-cigarette assemblies) high-precision body for musical instruments, such as pianos.

Further readings:

High precision seamless tubes and deep-drawn metal sleeves

Metal Expansion Joints

Convince as flexible elements

Ajsdfakdshfalkdsfhald asdkfhalskfja

Metallic compensators:

Absorb axial, angular and lateral movements

Kompensator rurowy:

Where piping designs are subject to thermal expansion, vibration or pressure, Mera Bellows metal expansion joints help to maintain the integrity of the system. Our bellows expansion joints are characterized by long lifecycle and can be manufactured in different ways.

Specialization into small compensator sizes with

the highest precision

Mera Bellows precision expansion joints can demonstrate their strength in a wide variety of applications with dimensions and pressure characteristics according to customers‘ demands. In our large-scale production we focus on relatively small wall-thickness and sizes of metal expansion joints. Product diversification through the supply of seamless and welded constructions

Not all applications necessarily require the advantages of seamless constructions. As a matter of cost effectiveness, we added seam-welded metal expansion joints to the product portfolio that are available in a wide variety of materials

Stainless steel expansion joints

High temperature variation, especially when occurring with large temperature gradients (e.g. observable in exhaust systems), accelerates material fatigue. For such applications, temperature-change resistant stainless steel is the first choice.

Applications:

Vibration isolation systems; compensation of cyclical movements in multiple directions, caused e.g. by motors, turbines, pumps or compressors; absorption of movements in pipe systems; flexible elements in solar thermal technology; air conditioning systems.

Further readings:

Metal expansion joints are used to absorb axial, angular and lateral movements