Custom-engineered solutions by Mera Bellows: Precision metal bellows and expansion joints that meet your needs

Demanding applications are our profession

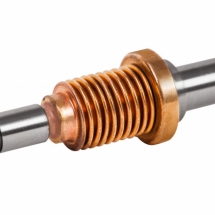

Metal bellows are key components in plenty of sensing, sealing, fluid handling and actuation applications. Different manufacturing methods and quality of material have significant effects on how reliably they perform in terms of stroke, pressure characteristics, spring rate and temperature response.

Pay attention to the difference between seamless and seam-welded designs. Depending on the requirements of a project, in many cases, formed bellows made from longitudinal seam-welded tubes may be the most cost-efficient solution – e.g. stainless steel bellows with simple compensation function. In the measurement and control technology, when very tight spring rate tolerances are relevant for the application, advantages of seamless metal bellows should be considered. Besides a low standard deviation in diameter and wall-thickness, the probability for micro leakages and contamination around the weld seam is reduced (e.g. for vacuum applications). They perform consistently and convince with a long cycle life in high-precision applications.

Typical applications

Typical applications

- HVAC (e.g. metal bellows as thermal actuators for thermostats)

- Medical engineering (pressure regulators)

- Energy generation- and distribution (nuclear valves, vacuum interrupters)

- Chemical industry (flow regulation)

- Automotive (various valves)

- Alarm/Warning systems (pressure switch with bellows actuator)

- Renewable energies (e.g. flexible connectors in solar thermal systems)

- Machine-engineering (bellows couplings, vibration isolation)

- Mining (regulation of conveyor belts)

- Vacuum technology (hermetic stem sealing in vacuum bellows valves)

- Deep drawn heater cups with axial rib-structure for electronic vapor devices, holding the cigarette)

- Aerospace (e.g. altitude sensors, bellows assemblies for Unmanned Aerial Vehicle Systems)